2023, here we are. . .

Wash the slate clean & get into it – literally wash with the amount of rain we’ve had post Xmas. The club’s website events calendar has been updated & there are a lot of events plugged in for this year, a good planning tool to schedule your race commitments for 23’.

New Year’s resolution, well, firstly burn off the Xmas food intake, sigh..

Secondly, don’t blame the race suit for shrinking, it is nooot the suuit & thirdly, get out & enjoy the splattering of events on offer.

Help out as a volunteer, spare a snippet of precious time to help out clubs run their events. Our club, local clubs, we all rely heavily on volunteers.

New series kid on the block, the North Island Rally Series; by the people, for the people.

Check out the 4th round – we’ll need a heck load of dedicated people to help out with this one, so members come forward, you’ve done it before, let’s do it again.

High five for a return of a clubman’s rally being held in our back yard.

Here’s to a good year.

I’m a glass half full kind of person so throw me a lemon & I’ll slice it up & add it to my mojito.

Go pedal foot poised for another year in the fast lane.

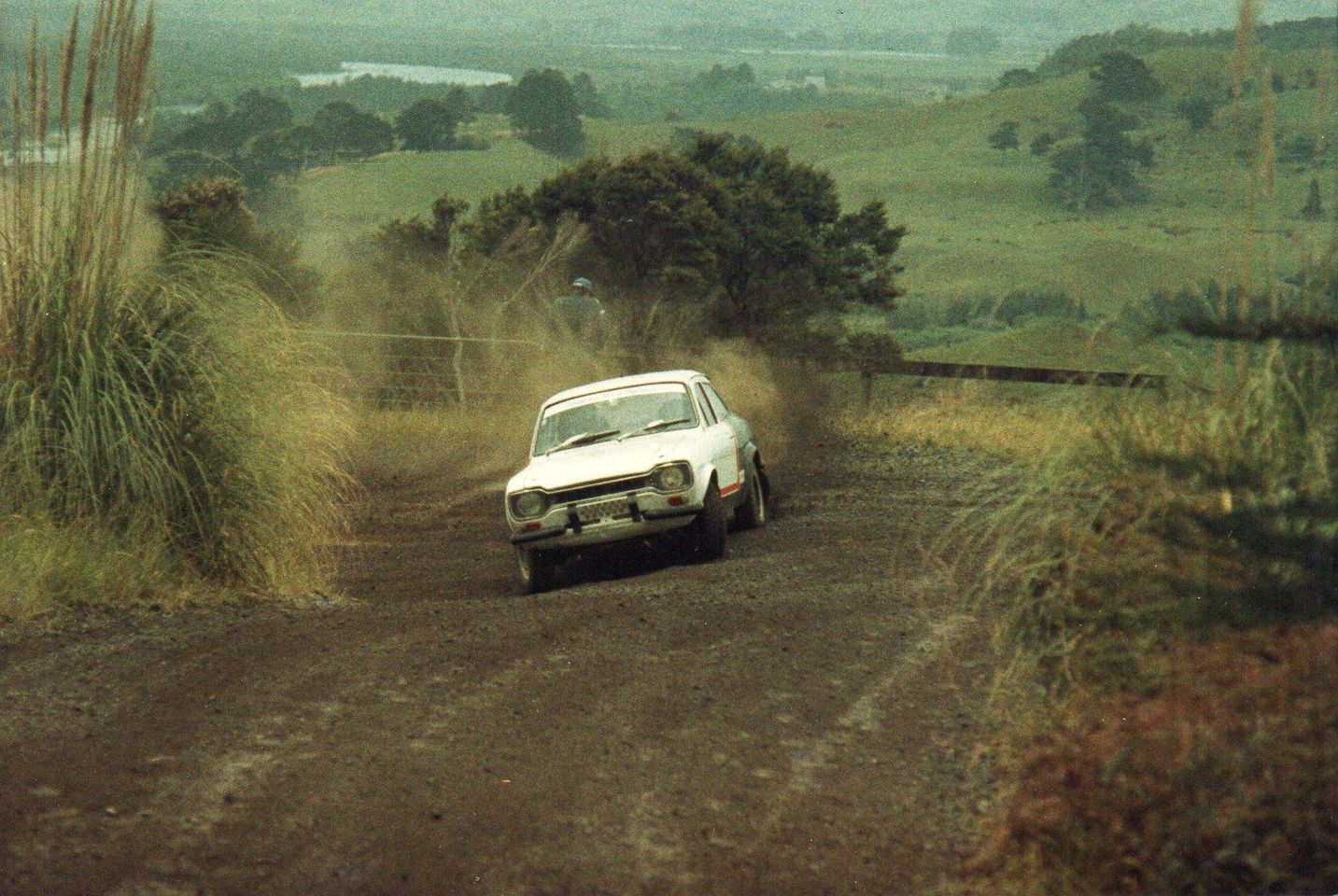

Here lies an iconic road, a hillclimb gem that’s back on offer & event entries are LIVE.

Thank the lord it’s still paved in gravel & not encapsulated in tarmac like many iconic kiwi roads.

This road is part of Pukekohe Car Club’s history & has been enjoyed over the years by many. Fellow racers alike enjoy the challenge of smashing times from previous years, the proof in the pudding you’ve still ‘got it’ if you end the day with a smile on your dial.

It’s a short, sharp burst up the hill, the technical aspects of the road burrowed into the memory banks of those who’ve concurred it & know it’s trade secrets.

She bites though, like most roads.

You’re fighting for 10ths, 100ths of a second to better previous finish times.

Above, a competitor from the mid-late 80’s laying down fast times.

Photo credit: Mungo Lloyd.

Here we are, some 40 years later, poised for another return.

Sun February 19th

Come & enjoy the return of Murray Road

If you’re local & want a better spectator seat for the day,

we NEED marshals

so shout out, click below;

Round 2 of the 23′ Northern Rallysprint Series.

Our annual shin dig, we’re back in Glen Murray to go fast & throw stones.

We are flipping the axis & aiming to run north to south to change the characteristics of this road & give drivers something a bit different.

Still unsure what to the pay the weather gods as a peace offering, we track the weather conditions leading up to the event. The ‘rural’ people sometimes know better as to what the weather has in store & this in turn will dictate how we run the course. The aim of the game is not to incur road damage!

This event will also act as the opening round of the newly formed

It’s great seeing this new series come alive, acting as a bridge from rallysprints to clubman’s rally level. The proceeding rounds being held more on a traditional clubman’s rally platform, full support going to this series & organizing clubs running the events.

Bothwill or Bothwont, this road will again be a part of the Northern Rallysprint Series. The event generates quality driver teams in challenging terrain, catching out even the best drivers at times.

Scheduled a couple of weeks before NZRC’s opening round in Otago, it lends itself perfectly for pre-testing seat time, a welcome introduction to the North Island Rally Series & a taste of humble pie being part of the popular Northern Rallysprint Series.

It’s on…

A local clubman’s rally out back, way yonder.

Maramarua Forest will set the scene later in the year for the return of the local clubman’s rally. Acting as R4 of the North Island Rally Series, local clubs will band together & combine forces to bring the rally back to the people.

Dust off the clipboards, it’ll probably have been a while since some of us have run one of these things. It is exactly what is needed though, an affordable, one day rally event where teams can arrive, compete & finish the day celebrating in a local setting.

Naturally, we’ll need the help of a lot of people to pull this thing off, so keep it on your radar & don’t be shy to reach out.

Procuring volunteers is like the scene in a western movie where the dudes are about to shoot & tumble weeds blow by, an eerie silence & not another being in sight.

Many hands make light work people, without you, we can’t pull it off so keep posted.

The Motorsport New Zealand POSSUM system is evolving into a modern, mobile friendly version with a national roll out scheduled for mid 2023.

This new platform will allow ease for organizers & competitors a like. The days of not racing if you’ve forgotten your plastic competition license will be a thing of the past.

After a brief glimpse into what is in store, I am signed – the sales pitch is looking good while I still clutch the logbook in hand.

Always tedious learning new software, a leap forward in the right direction here is welcomed, the proposed software capabilities significant whilst still being very user friendly.

There will be a dedicated MSNZ helpline available when it goes live.

This is one to embrace, not shy away from.

Understanding Oil Lubrication & Contamination Control

This Isn’t Your Grandfather’s Engine Oil

A great deal of research and new technology have advanced the fields of oil lubrication and

contamination through oil filters. If you still think (as many do), that “All oil filters do the same thing, so why pay more for a brand name?” then it may be time to reconsider.

Lubrication research continues to improve how lubricants (such as oils) protect moving parts, increase fuel economy, and extend the life of your engine. The lubrication industry has continually upgraded the quality of engine crankcase oils, grease (chassis, wheel bearings), transmission fluids, hydraulic fluids, gear oils, and brake fluids.

The thought that all oils are the same implies that a piece of equipment built five years ago requires the same lubricants as the same type of equipment being built today. But fuel conservation, lower emissions, new materials, and better manufacturing (tighter equipment tolerances) all combine to require specialized oils and filters for today’s equipment that older models did not have.

As lubrication needs have evolved, trucks, planters, harvesters, sprayers, trailers, and car engines depend on the proper oil to keep internal parts operating and functioning properly within the equipment specifications. As equipment specifications change, manufacturer’s design and upgrade oil lubricants to meet the new demands. That’s why it is important to identify and select the proper oil and filter based on the equipment manufacturer rather than basing your selection on cost.

Performance and compatibility must come first; price should come second.

While lubricants and filters may look similar and be packaged alike, remember that it’s what you don’t see

inside the product that allows it to perform a certain way. Separating products that perform well from

those that do not perform as well can be challenging, because the technical information is conveyed in a

coded language consisting of numbers and abbreviations. These numbers and abbreviations are the

industry standards that lubricant manufacturers use when they build their products.

The purpose of this article is to demystify these numbers and abbreviations so that you will be able to

distinguish the differences between oils and oil filters. Understanding these terms will help you choose

the best (which is not always the cheapest or even the most expensive) engine oils and oil filters for your

equipment and application. In the long run, choosing the correct oil and filter will increase equipment

reliability, enhance operating performance, lower maintenance costs, and extend your equipment’s service

life.

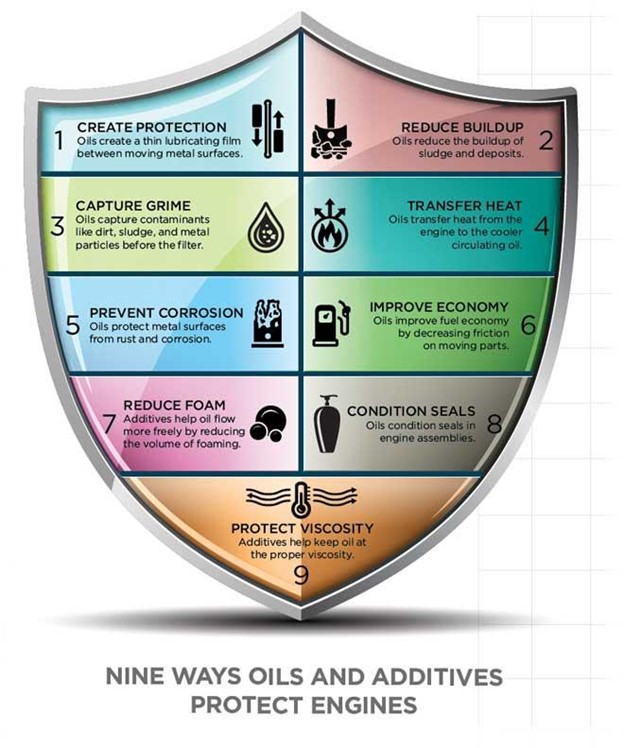

Engine Oils Offer Multiple benefits

Retailers have shelves filled with multiple brands of engine oils. Each manufacturer claims their product

offers one advantage or another over the competitors. Most engine oils, however, are similar in that they

are designed to meet basic engine specifications, such as:

How quickly the oil can lubricate the moving parts in a cold engine

How well they protect parts at higher engine temperatures

How soon they break down

The recommend interval between oil changes

Conventional engine oils begin life as crude oil pumped from underground reservoirs. Raw crude contains impurities that need to be removed and require further refinement to get the oil to a specific viscosity. Conventional engine oils consist of approximately 80 percent refined crude oil (called base oil). The remaining 20 percent are additives that serve numerous purposes, such as enhancing base oil properties, suppressing certain base oil properties, and adding new properties to the formulation. Usually, these additives are what distinctly separate one crankcase oil product from another.

- Crankcase oils protect engines by:

- Creating a thin layer of lubricating film between the metal surfaces that slide or roll against each other. This layer reduces friction and wear.

- Reducing the buildup of internal sludge and deposits.

- Transporting or dispersing contaminants such as dirt, sludge, soot, and metal particles. These contaminants are removed when the oil passes through the filters.

- Transferring the heat generated by the engine into the “cooler” oil circulation.

- Protecting metal surfaces from rust and corrosion.

- Improving fuel economy by decreasing friction between moving parts.

- Helping the oil pump deliver the correct value of oil more effectively by reducing the amount of bubbled air throughout the body of the oil and foam or froth.

- Conditioning engine seals to reduce leaks.

- Maintaining acceptable viscosities (thicknesses) for hot and cold operating temperatures.

And you thought oil was only for lubrication!

Make The Oil Work for You

Make sure to change oil and filters at the intervals the manufacturer recommends.

If you wait to change the oil, it’s not a linear degradation. In other words, there is a sharp fall-off in engine oil performance. If you are a short-trip driver, it is probably beneficial to change the oil more frequently. If you are a long-haul driver, you can extend the oil change somewhat.

If the vehicle is newer you can extend it. If the vehicle is older, then it will require more frequent oil changes. Many factors influence an oil’s life expectancy, but at the end of the day, you need to change the oil and filter at timely intervals to avoid permanent engine damage.

Temperature Controls Viscosity

Temperature determines how easily an oil will flow through an engine and the thickness of the oil lubricating films. The temperature inside a gasoline or diesel engine can reach 300ºF or greater for brief moments. This is important, because at higher temperatures, oils get thin and flow more like water.

In fact, the oil can get so thin that it cannot provide the oil-film thickness that separates the two moving surfaces it is trying to protect. Most parts need to basically “hydroplane,” just as worn tires on a wet pavement do. Engines need a minimum viscosity to achieve the separation between parts, but the specific viscosity engines need is based on the specific parts, engines, temperatures, speed, and loading.

When it’s cold, oil can thicken and flow more like molasses. When you start an engine under these cold conditions, the oil residue that is protecting your engine components is what was left when you last turned off the engine. When you start an engine in cold weather, there is a brief moment when fresh oil from the oil pan does not flow and circulate in all zones of the engine. It takes more time for the oil to move from the oil pan to fill some vacated cavities, lines, and components that might have been drained slowly while the engine was at rest.

During start up, there might be metal-on-metal contact — there may be even more if you are using the wrong oil. This is called a dry start condition, and is the source of a high percentage of all engine wear. This is why manufacturers recommend that you do not operate your cold engine at a high RPM until the engine oil pressure gauge rises and stabilizes for several seconds.

Think of pouring honey after letting it sit in the refrigerator overnight. The honey will thicken to the point that it barely moves when you turn the jar upside down. If you put the same honey in a microwave and heat it up for a minute, it will flow like water.

Petroleum engineers and chemists formulate oils to accomplish two major goals:

- To be thick enough to provide a lubricating film at hot temperatures

- To be thin enough at cold temperatures to move quickly from the oil pan into and through the engine’s moving parts

They can accomplish these goals by using additives called viscosity index improvers in engine oils. Synthetic lubricants require fewer of these additives, because they have naturally high VIs. The higher the VI, the less viscosity changes with the temperature.

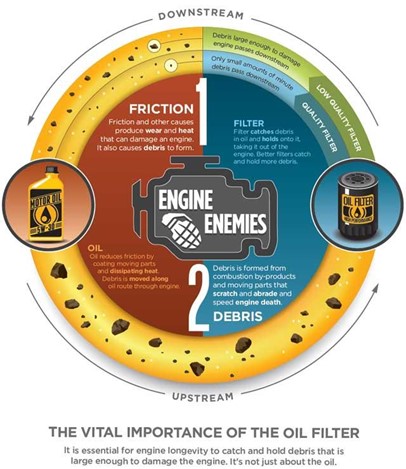

Don’t Forget The Oil Filter

Many operators never give the oil filter a second thought — as if it isn’t very important to an engine. It’s common to replace the used engine oil with a high-quality oil, then turn around and pick the cheapest filter possible. Some even try to save money by replacing the filter every other oil change. So, it might come as a surprise that if you had to choose between buying a better oil or a better filter, it is often better to spend money on a better filter.

Remember that the main purpose of oil is to coat metal parts that move. While oil circulates throughout the engine, it will pick up small pieces of debris that can wedge into narrow gaps. The debris that lodges between moving parts can pit and abrade metal. This circumvents the protection the oil is supposed to provide.

The oil and filter must work together to protect the engine from these microscopic, abrasive metal flakes that are by-products of combustion, dirt, and dust. If you install a less effective filter, or leave a filter on too long, it can be just as bad as operating an engine with oil past its prime.

An under performing filter can negate the protection a premium oil provides, and so accelerate engine wear, affect reliability, and diminish service life. The takeaway message is that an oil’s ability to protect the moving parts in an engine from wear is only as good as the filter and its ability to remove contaminants from that oil.

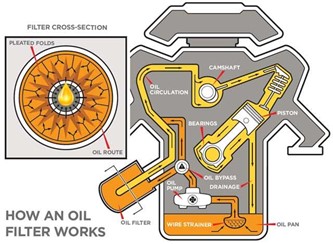

To better understand how a filter removes and retains particles, it’s important to understand the filter’s design and how oil moves in and out of the canister.

How Oil Flows

The filter is located between the oil pump and engine. When the engine is running, it first pulls oil from the bottom of the oil pan through a wire cloth strainer, and then pumps it to the filter. Once to the filter, the oil will pass under pressure through the smaller inlet port that forms a concentric circle around the opening at the top of the filter.

Most oil filters have an outside to inside flow. Oil starts on the outside of the pleated filter elements and flows inward to the center tube. The pleated filter medium can be made of paper, glass fibers, or a blend of both.

Inside the filter, the oil follows the path of least resistance — it first goes through the largest pores of the filter paper (media) and into the perforated center tube. Over time, as the larger pores become blocked, the oil is forced through smaller pores until all of the pores are plugged. The filtered oil will exit through the center port and on to the engine through a series of manifolds to reach different parts of the engine. Oil then flows down into the pan by gravity where it begins the journey again.

A mechanical adaptation built into engines is to reroute the oil flow when the filter gets clogged. There is a fail-safe bypass value on the engine block just in case the flow is severely reduced from a clogged filter. This allows oil to continually flow even when the filter is plugged. It’s important to remember that the oil lubricating the engine will be unfiltered when it is in this bypass mode.

Properly Dispose of All Products

It goes without saying that we all need to dispose of used oil and oil filters so that we do not contaminate land or water. One quart of oil has the potential to contaminate up to 250,000 gallons of drinking water or produce an oil film over a 2-acre pond. With the high risk for affecting water, mismanaging used oil drained from an engine or oil remaining in a filter or jug is not an option.

The key to properly managing oil filters is to completely drain them before disposal.

Conclusion

The oil and filters you choose greatly affect your equipment’s reliability and life expectancy.

If you intend to run equipment to the end of its useful life or extend its normal service life, then you really need to educate yourself about the oils and filters you use in that equipment. Consider the money you have invested in purchasing trucks, sprayers, mowers, planters, combines, and other equipment. That investment should convince you that knowing more about the oils and filters you use to protect that equipment is a high priority.

You can go cheap and save money now. But in the long run, it may cost more when your equipment breaks down and is prematurely damaged due to the wrong oil or and under performing filter.

You can just as easily overspend on exotic oils and fancy oil filters that deliver little return on investment — or the benefit will only be gained by the next owner of the equipment after you sell it.

This is why it is important to remember: Select lubricants more on what the lubricant is designed to do rather than its cost.

Think performance first, price second. By making better selections, you should expect increased fuel economy, lessened emissions, and extended life expectancy of equipment.

Oils have come a long way since the 1960s. They last longer and maintain their viscosity better under strenuous conditions. But choosing the wrong oil for the wrong application can be costly. Read the owner’s manual for your vehicle to be sure you purchase oil, and realize what all the numbers on the jug of oil mean before you dump just any old oil into your equipment.

Going cheap and saving money in the short run may cost you big in the long run!

Email Speedhub

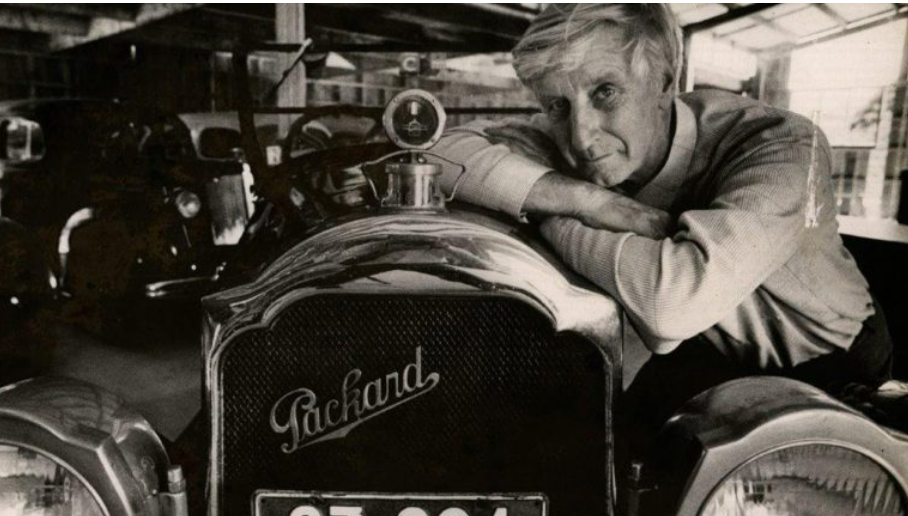

Graeme Craw, farmer and earth-moving contractor, founded the collection back in the late 1950s. His strong interest in the Industrial Revolution and its impact on early New Zealand society led him to start preserving the machines and their stories which came out of this era.

He was one of the first collectors to put together a collection of one make of vehicle showing its chronological development in design and technology.

The collection encompasses vehicles, machinery and memorabilia from the 19th and 20th centuries including the 1873 Dubs A62 steam engine.

Graeme started his love of the American manufactured Packard automobile when he purchased ‘CD9,’ a 1924 Packard straight-eight Tourer; ‘A gentleman’s car made by gentlemen’. Today the collection encompasses 55 of these outstanding automobiles, covering most models from 1919 to 1958 when Packard ceased production.

At Maungatapere, Graeme took visitors and clubs through the collection by appointment. However after a long illness, Graeme passed away in 2007.

After Graeme’s death the family decided to hire a manager and once again open the collection to the public as this had been Graeme’s wish.

Today, Graeme’s son Fenton and his wife Geraldine direct the museum and the collection is open to the public Wednesday to Saturday, 10.00am to 4pm.

Pukekohe Car Club

Pukekohe Car Club